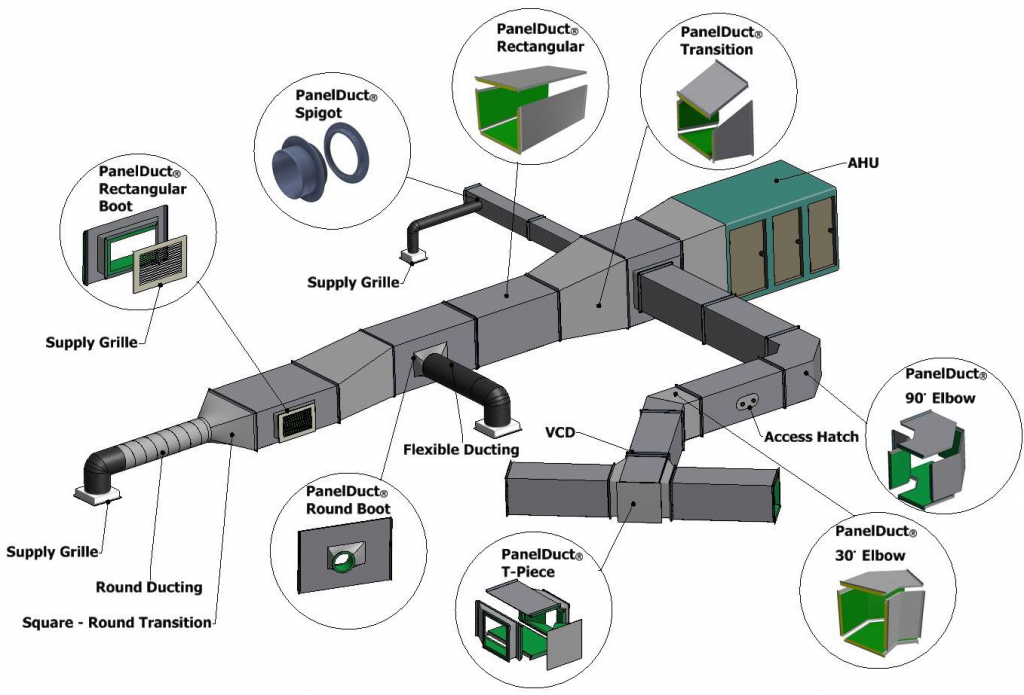

PanelDuct® is a ventilation duct system composed of flat pack panels which push fit together onsite.

The panels have an exterior casing of galvanised steel, ensuring durability. This encapsulates a 35mm thick layer of flame retardant foam, which provides thermal insulation. This foam is internally faced with embossed aluminium liner.

The ends of each panel are protected by a structural aluminium flange. Each panel has a locking profile along its edges, which contains an integral seal. This seal prevents air leakage along the edges after panel assembly.

Four panels push fit together to form a rectangular duct section.

A flange end seal, is placed on either end of each duct section to prevent air leakage between duct sections after assembly.

Duct sections are fastened together with standard flange clamps.

PanelDuct® Technical Attributes

1. Panel Profile Seal

- 8x10mm expanded silicone sponge

- Compressed during assembly to ensure airtightness

2. End Flange

- 2mm thick aluminium extrusion

- ‘Glove’ design protects duct ends

- Provides smooth surface for flange end seal

3. Durable Galvanised Steel Outer Skin

- Provides impact protection

- Lightweight 0.5mm guage metal

- Galvanised to provide corrosion resistance

4. Duct Corner Piece

- 3mm steel

- Aligns panels flush during assembly

- Adds to duct rigidity

- Corner holes align duct sections

5. Inner Lining Seal

- Seals between panels internally

- Foam core with exterior liner

6. Flange End Seal

- 6x15mm polyethylene foam tape

- Seals between duct sections

- Partially shown, this needs a complete loop when installed

7. Aluminium Foil Internal Lining

- 0.5mm stucco embossed

- Provides easy clean surface

8. Corner Seal

- Butyl material with plastic facing

- Ensures corners are airtight after duct assembly

9. Flame Retardent Foam Insulation

- 40kg/m3 density

- 35mm thickness

- U-value 0.62 W/(m²k)

The interlocking design of the panels is fully patent protected, as is the process by which they are made.

See all our certifications and patents

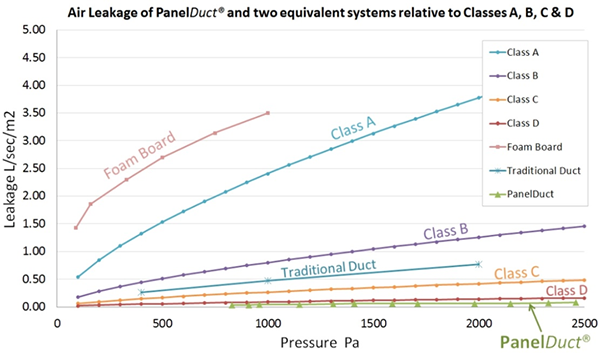

PanelDuct® Air Tightness

Ventilation systems built with PanelDuct® has virtually no air leakage, even at 2000Pa, which far outperforms any other system currently available. Pressure tests have been conducted on a sample installation using the standard PanelDuct® flange coupling system.

The same tests were repeated for equivalent pre-insulated systems and a traditional system of equal shape and size.

The results of the test are shown to the right here and show the unpresedented level of airtightness compared with existing systems.

PanelDuct® is installed in a single fix with a self-aligning assembly that requires no hardware or tape.

The patented interlocking system of compression seals and innovative flange design eliminate the possibility of any gaps.

PanelDuct® is delivered to site in flatpack form, requiring only 20% of the usual storage space.

PanelDuct® is suitable for any insulated ventilation application, particularly in high specification projects where pressurised clean air delivery is assured at minimal operating costs. The system can be installed in both new build and retrofit projects and is fully compatible with standard galvanised sheetmetal ductwork.

PanelDuct® is available in 22 widths: from 150mm up to 1200mm.

If a width of more than 1200mm is needed, any two panel widths can be joined together by hardware-free H-flanges to produce compound panels of the required width.

Any duct is composed of two horizontal and two vertical panels. Any size of side panel can be assembled to any of the sizes of top & bottom panels. Our range of 22 sizes of panels allows a choice of 22 horizontal sizes and 22 vertical sizes, meaning that a total of (22×22) = 484 rectangular cross-sections are possible.

The same is true of elbow, bends and transitions: each side of a PanelDuct® system is fully interchangeable with the entire range of panel sizes. This is a feature that is unique in the ventilation industry: a limited size of panel widths can be used to generate a huge matrix of potential sizes, enabling a fully modular flat pack concept to become a commercial reality.